high infeed palletizer

The fully automatic high-position palletizer produced by bremetz is a frame-type high-position palletizer. It has the characteristics of high palletizing speed and high palletizing stability. It is mainly used for palletizing of fine powder in the building materials industry, such as high-speed palletizing of cement, silica, putty powder, gypsum powder, starch, flour bags.

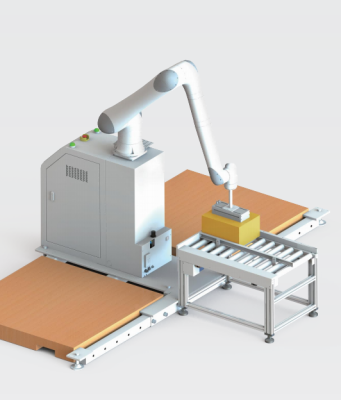

Conventional palletizer from toptier produced by bremetz is part of the filling and palletizing production line. It usually forms a complete set of packaging and palletizing production line suitable for fine powder together with automatic bag feeding machine, automatic filling machine, conveyor line, online wrapping machine and pallet magazine system.

High-position palletizer is an automated equipment designed for high-density and high-stack scenarios. It can accurately stack goods to a specified height (usually up to 3-5 meters) and is widely used in food and beverage, chemical, building materials and other industries.

1. Equipment definition and core functions

Definition: Through the lifting mechanism, robotic arm or gantry structure, the packaged goods (boxes, bags, barrels, etc.) are stacked on high-position pallets (or directly sent to three-dimensional shelves) according to the preset mode, supporting unmanned operation.

Core functions:

High-position stacking: The vertical lifting height can reach more than 4 meters to meet the needs of three-dimensional warehousing.

Multi-form compatibility: supports a variety of packaging forms such as boxes, bags, and drums.

Precise positioning: servo system control, repeated positioning accuracy of ±1mm, to prevent goods from tipping over.

High-speed operation: The beat can reach 15-30 times/minute, meeting the efficiency of continuous production lines.

2. Key modules:

Lifting mechanism: lead screw/chain drive, equipped with guide rails to enhance stability.

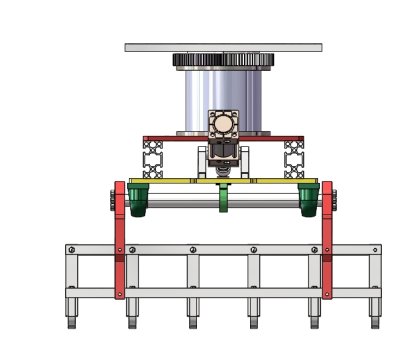

Grabbing device: vacuum suction cup (carton), plywood (woven bag), clamp (barrel), etc.

Conveying system: roller/belt line connects packaging machine and palletizing position, with automatic pallet supply function.

Control system: PLC+touch screen, supports multi-pallet programming (such as stacking, staggered).

III. Typical application scenarios

1. Food and beverage industry:

Case: A brewery uses a high-position palletizer to stack 24 bottles/box of beer on a 2.5-meter-high pallet, with a single-line capacity of 2,000 boxes/hour.

2. Chemical and building materials:

Case: A fertilizer plant stacks 50kg bagged products to 4 layers (total height 3.2 meters), and the pallet load reaches 2 tons.

3. E-commerce logistics:

Case: The logistics center uses a high-position palletizer to deliver express boxes directly to the three-dimensional shelf, saving secondary handling.

Through the application of high-position palletizers, enterprises can significantly improve storage density and logistics efficiency. For example, after a flour mill introduced the system, its storage capacity increased from 5,000 pallets to 8,000 pallets, and the efficiency of its packaging line increased by 35%. When selecting a model, it is necessary to comprehensively evaluate production capacity, cargo characteristics, and intelligent requirements, and give priority to solutions that support modular expansion.