palletizer & depalletizer for corrugated paper

The depalletizing and palletizing system solutions for corrugated paper produced by bremetz are common operations in the fields of logistics, warehousing and manufacturing, involving unloading corrugated boxes from pallets (depalletizing) or stacking them on pallets in a regular manner (palletizing).

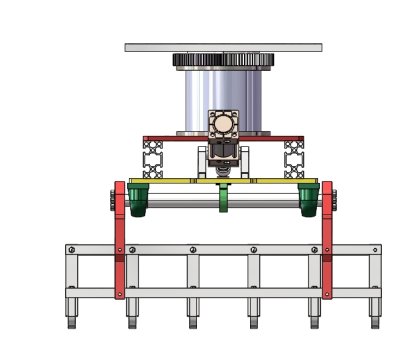

Its main equipment includes palletizing robots (BS180-3100), customized fixtures, fully automatic pallet magazine systems, paper pads, control integration, conveyors, etc.

Depalletizing and palletizing of corrugated paper are common operations in logistics, warehousing and manufacturing, involving unloading corrugated boxes from pallets (de-palletizing) or stacking them on pallets in a regular manner (palletizing).

Equipment includes:

Robotic arm: equipped with a vision system and clamps (vacuum suction cups, grippers, etc.) to identify cartons of different sizes.

Depalletizing robot: suitable for high-speed, repetitive operations, such as e-commerce warehouses.

Visual recognition: locates the position of cartons through 3D cameras or laser scanning.

Fully automatic palletizer: integrated conveyor belt, diverter and flattening device.

Path planning: optimizes the movement trajectory of the robot arm to avoid collisions.

Advantages: high efficiency (up to 1,000 boxes/hour), reduced labor intensity.

Pattern algorithm: generates stable stacking solutions (such as 5-layer cross stacking).

Adaptive adjustment: dynamically adjusts the clamping force according to the size of the carton.

Core equipment and technology

1. Robotic fixture:

Vacuum suction cup: suitable for corrugated cartons with flat surfaces.

Mechanical gripper: suitable for special-shaped or easy-to-slide cartons.

2. Vision system:

3D cameras (such as Keyence, Cognex) scan pallets and carton positions in real time.

3. Control system:

PLC or industrial PC integration, support data interaction with WMS (warehouse management system).

Notes

1. Carton strength: avoid stacking too high to cause the bottom carton to collapse (generally recommended not to exceed 1.5 meters).

2. Pallet standard: follow ISO or industry pallet size (such as 1200×1000mm).

3. Environmental factors: Excessive humidity may cause corrugated paper to deform, and the storage environment needs to be controlled.

4. Safety protection: Automated equipment needs to be equipped with protective measures such as gratings and emergency stop buttons.

By choosing a reasonable depalletizing and stacking solution, companies can significantly improve efficiency (automated system efficiency can be 3-5 times that of manual work), while reducing cargo damage and labor costs. If more specific equipment selection or solution design is required, it is recommended to further provide parameters such as carton size and throughput.