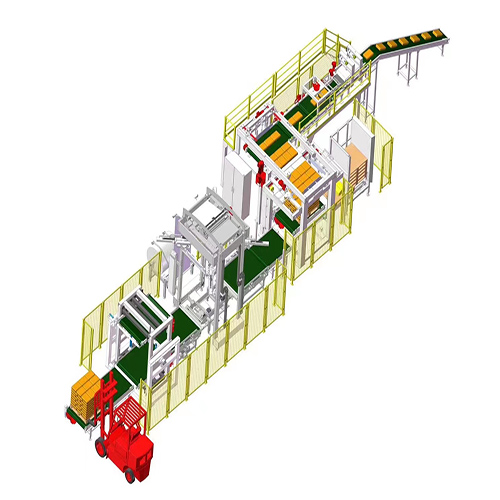

Mortar cement gypsum putty powder bag filling and palletizing production line

The automatic bag feeding, automatic filling and automatic palletizing production line produced by bremetz for the building materials industry is widely loved by consumers for its high filling speed, fast palletizing speed, high production stability and high efficiency. The main equipment includes automatic bag feeding machine, automatic filling machine, high-position palletizing machine, automatic pallet warehouse, online wrapping machine. It is widely used in filling and stacking putty powder, cement, gypsum, mortar, sulfur powder and other fine powders. It is a solution designed for building materials

The mortar cement packaging and palletizing production line is a comprehensive system that integrates automated packaging, conveying, and palletizing. It is widely used in mortar packaging and palletizing, cement packaging and palletizing, putty powder packaging and palletizing, and gypsum packaging and palletizing in the building materials industry.

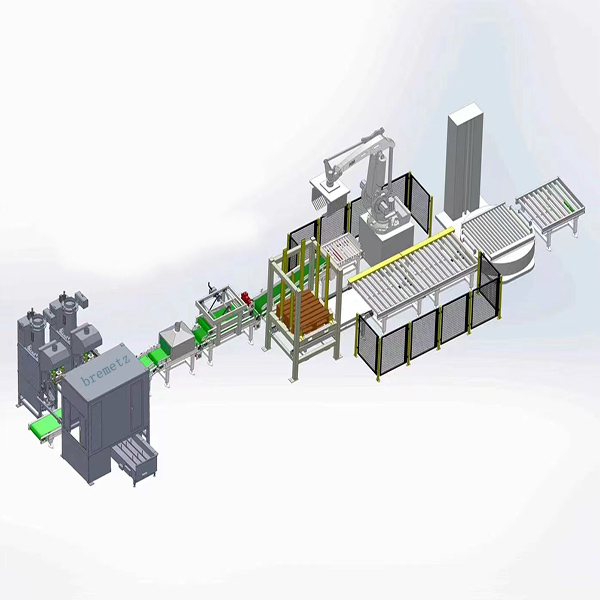

1. Core components of the production line

1. Packaging module

-Including automatic packaging machines, bag supply machines, heat sealing machines, etc., supporting a variety of packaging materials (such as woven bags, paper bags), the packaging specifications are usually 20-50kg/bag, and the packaging speed can reach 800-1600 bags/hour.

2. Conveying and detection module

Equipped with bag-inverting conveyor, re-inspection scale, rejection device, etc., to ensure the accuracy of packaging weight (≤0.2%), and complete standardized processing through shaping machine and inkjet printer.

3. Palletizing module

-Use BS180-3100 robotic arm or frame-type high-position palletizer, combined with PLC control and touch screen operation, to achieve pallet stacking, support teaching programming to flexibly adjust the palletizing mode.

4. Auxiliary system

- Integrated dust removal system (air volume 1500-2000m³/h), electronic control system and network monitoring function to achieve remote fault diagnosis and production management.

2. Technical features and advantages

1. High degree of automation and flexibility

Adjust parameters through the touch screen to adapt to different packaging sizes and pallet specifications, without mechanical reconstruction, significantly improve the flexibility of the production line.

2. Energy saving and high efficiency

Energy consumption is reduced by more than 80%, and the packaging efficiency is more than 1,000 bags per hour.

3. Manual operation replacement

Avoid manual operation in dusty environment, reduce the risk of occupational diseases such as pneumoconiosis, and save 4-6 labors for a single line.

4. Intelligent management

Support docking with the factory MES/ERP system to achieve real-time monitoring and optimized scheduling of production data.

3. Typical application scenarios

1. Dry mortar production

Suitable for automated packaging and palletizing of bagged products such as gypsum mortar and thermal insulation mortar, and the sealing design reduces dust leakage.

2. Cement and building materials industry

Replace manual feeding and handling, improve workshop environment, such as a building materials factory in Weishi that realizes feeding-mixing-packaging integration through a fully automatic line.

Through the above solutions, enterprises can significantly improve packaging and palletizing efficiency (such as reducing manual speed from 2 minutes/pallet to 20 seconds), while reducing comprehensive operating costs by about 30%. The specific selection needs to be combined with production capacity requirements, material characteristics and budget