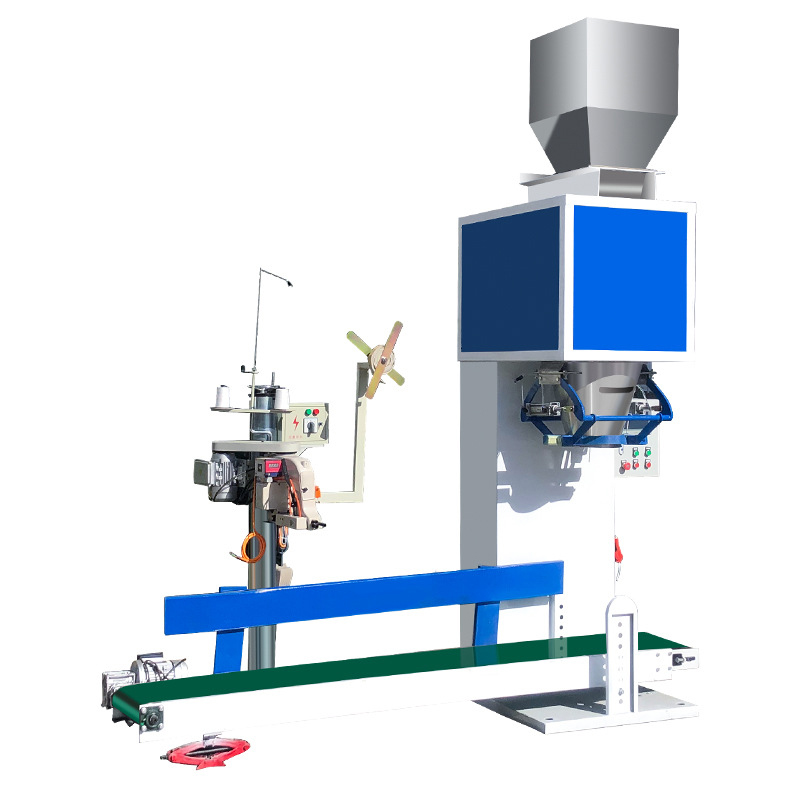

grain bag filling machine

The granular quantitative scale is a filling machine used for automatic weighing and packaging of granular materials. It is widely used in many industries such as chemical, food, pharmaceutical, and agricultural industries. For example: grain filling, rice filling, soybean packaging, and nut packaging.

Grain filling machines achieve precise measurement through weighing sensors and control systems. Its workflow usually includes the following steps:

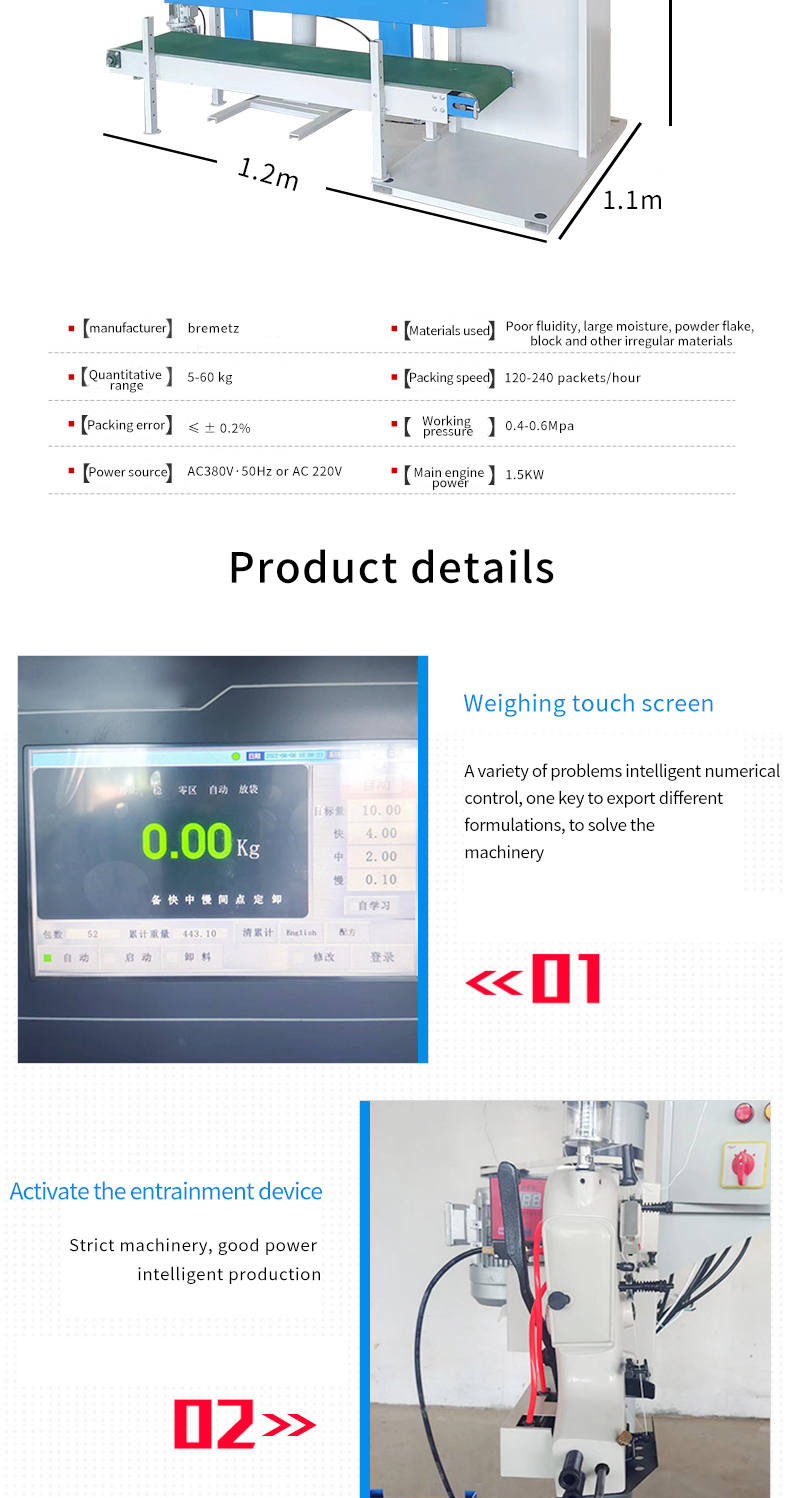

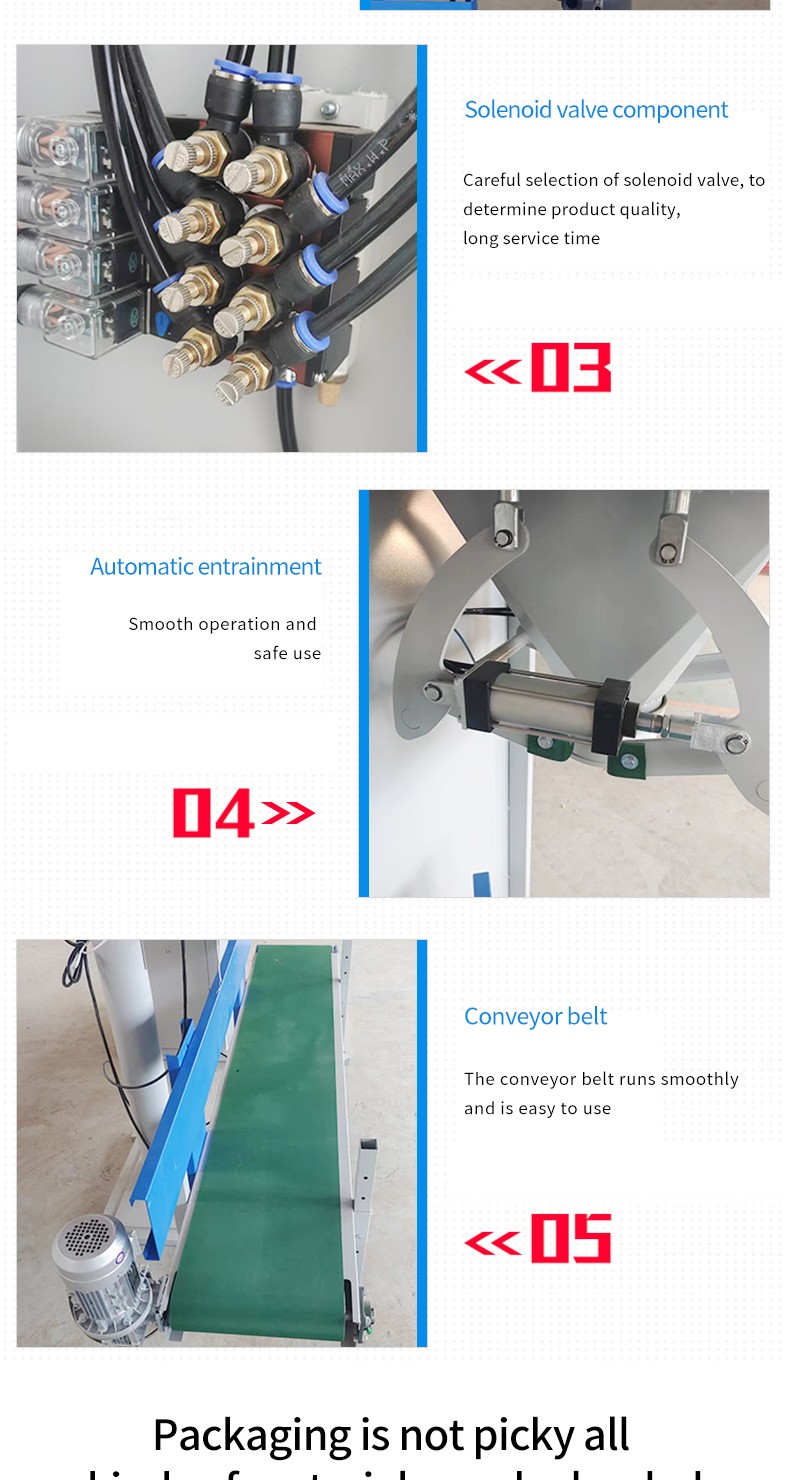

1. Feeding stage: adopt fast, medium, and slow multi-level feeding methods (such as fast feeding, medium feeding, and slow feeding). When the material weight is close to the preset value, the feeding speed is gradually reduced to improve accuracy.

2. Weighing control: The sensor monitors the weight in real time, and the control system adjusts the feeding door switch according to the preset parameters to complete dynamic weighing.

3. Unloading and packaging: After weighing, the material enters the packaging bag, the bag clamping device is automatically released, and the packaging bag is sent to the sewing or sealing station via the conveyor belt for circulation.

Structure and technical features

Core components:

Weighing unit: including weighing bucket, sensor, and load-bearing bracket, which directly affects accuracy and speed.

Feeding mechanism: pneumatic gate, auger or belt conveyor, some models use three-level feeding (fast, medium and slow).

Control system: integrated PLC or intelligent instrument, supporting automatic calibration, data storage and remote communication (RS232/485 interface).

Application field

The big bag filling machine mainly serves the following industries:

1. Chemical and building materials: quantitative packaging of fertilizers, plastic particles, inorganic salts and other materials.

2. Food and agriculture: grain, feed, seeds, etc., need to avoid extrusion or agglomeration.

3. Medicine and light industry: scenes with high precision requirements such as pharmaceutical particles and additives.