Deicing agent palletizing machine palletizer

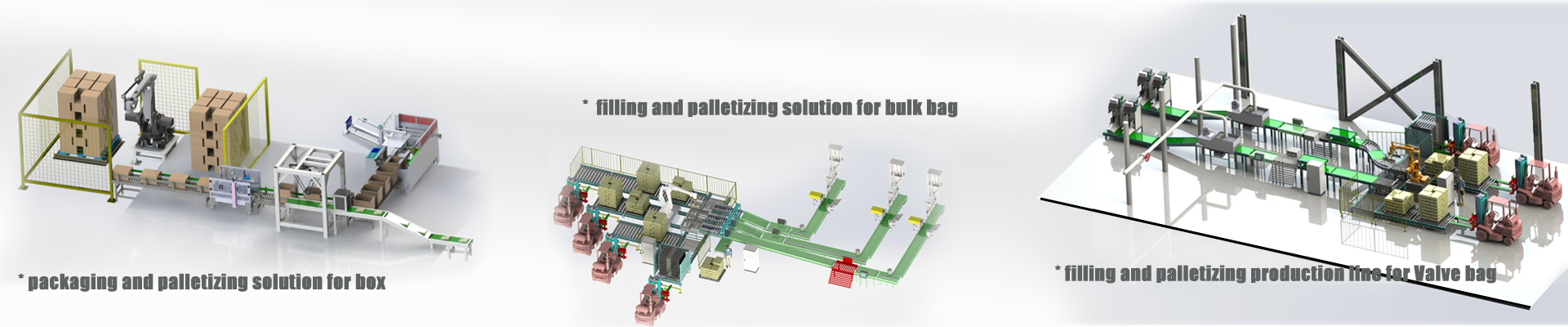

Bremetz manufactures and designs palletizing equipment solutions tailored to the palletizing needs of products like de-icing agents, depending on their packaging type (bags, drums, boxes), corrosiveness, and environmental requirements.

I. Palletizing Equipment Matched by Packaging Type

1. Bags of de-icing agents (e.g., 25kg Rock Salt, Ice Melt Pellets)

Recommended Equipment:

Robot Palletizer (with gripper)

Gripper Type: Pneumatic Clamp (anti-slip design, suitable for woven and plastic bags)

Speed: 600-1200 bags/hour

Fully Automatic High-Level Palletizer (suitable for standard pallets)

Adjustable number of layers, automatic flattening

Special Requirements:

Dust-proof design (prevents flying salt dust)

Corrosion-resistant body (salts absorb moisture and corrode metals)

2. Barreled liquids (e.g., Brine, Liquid Salt, Beet Juice) Blends)

Recommended Equipment:

Gripper: Bucket-Type (Suitable for 200L plastic/metal barrels)

Load Capacity: ≥150kg/barrel

Gantry Palletizer (Heavy-Load, Suitable for High-Speed Production Lines)

Positioning Accuracy ±2mm

Special Requirements:

Leak-Proof Design (Bag Sealing Detection)

Stainless Steel (Chloride-Resistant)

3. Case Packaging (e.g., Driveway Salt, Pet-Safe Ice Melt Small Packages)

Recommended Equipment:

Parallel Robotic Palletizer

Speed: 80-150 times/minute (Suitable for light and small boxes)

Low-Cost, Suitable for Regular Cartons

II. Functional Design Optimized by Product Characteristics

1. Corrosive Products (CaCl₂/MgCl₂) De-icer

Protection Measures:

Equipment Material: 304 stainless steel/PP plastic covering key components

Lubrication System: Salt-mist-resistant grease

Electrical Cabinet: IP65 protection

2. Eco-friendly Melt, Acetate-based

Cleanliness Requirements:

Easy-clean structure (no dead corners)

Food-grade lubricant (to prevent contamination)

3. Airport/Highway Design (Airport Runway De-icer)

High-Intensity Operation:

24-hour continuous operation capability

Explosion-proof configuration (optional for flammable environments)

III. Typical Palletizing System Configuration Example

Case Study: 25kg Bag Rock Salt Palletizing Line

Component Specifications

Conveyor: Belt-type (with weight detection)

Shaping Machine: Automatic bag tapping/flattening

Palletizing Robot: BS-180-3100 (180kg payload)

Gripper: Pneumatic clamp (with pressure feedback)

Pallet Storage: Automatic feeding (5 pallets capacity)

Control System: PLC + HMI (supports recipe switching)