Application of truck bag loader intelligent loading system in cement industry

Application of intelligent loading system in cement industry

Manual loading of bagged cement is extremely harmful to human health, so it is imperative to replace manpower with automatic loading solutions, so the intelligent loading system came into being. This article mainly introduces the structure, functional characteristics, operation mode, core technology, market application and other aspects of the intelligent loading system for bagged cement in the packaging workshop of cement plants.

Intelligent loading system solutions and features

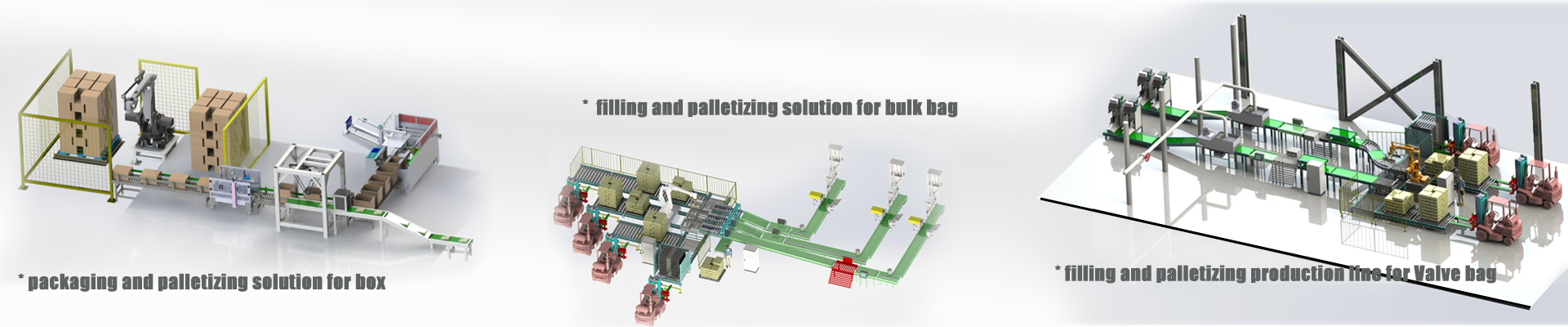

There are two main loading operation modes in cement plants: offline loading and online loading.

1. Offline loading

Offline loading refers to some places that require continuous production or production peak shifting, that is, in the absence of shipping orders, customers carry out packaging production and palletizing on pallets by themselves; after palletizing, they are stored in the warehouse. Once customers have order requirements, the products in the warehouse will be sold first. At this time, customers can sell whole pallets or depalletize the whole pallet. After the products are depalletized into loose bags, the loose bag products are transported to the automatic loading robot through the conveyor line. The automatic loading robot automatically loads according to the customer's order. After loading is completed, the vehicle leaves the lane. The specific application scenario is shown in Figure 1

2. Online loading

Online loading means that after the vehicle arrives at the loading lane, the customer starts the packaging machine and then performs bulk bag packaging; after the bulk bag packaging is completed, the bagged products are sent to the loading robot through the conveyor line, and the loading robot automatically loads the vehicle according to the customer's order. After the loading is completed, the vehicle leaves the lane. The specific application scenario is shown in Figure 2.

It should be noted that, whether it is offline loading or online loading, the core intelligent loading robot in the solution is the same system. In actual applications, offline loading and online loading are also made into the same large system, which can further improve the utilization rate of the intelligent loading system. The intelligent loading system is composed of automated machinery, application software, vehicle detection system, video analysis, and dust collection system. Machinery replaces personnel to perform high-load physical labor; the dust collection system ensures cleanliness and dust-free during the entire loading process; the software system is the brain of the entire product. Through the flow of data, human intervention is reduced, making the entire product more intelligent, safe and controllable. Its operation mode is as follows: After the empty truck arrives at the designated area, it does not need to move. The intelligent loading system automatically identifies the vehicle model according to the total loading weight pushed by the order system, and then automatically arranges the loading stack type according to the size of the carriage. The loading machine automatically packs and loads the finished product. The loading machine is equipped with two counting methods: infrared detection and mechanical counting. The storage system interface is reserved. After the loading is completed, voice and screen prompts are output, and the truck leaves. It can be seen that the intelligent loading system can fundamentally realize the dust-free, digital, and unmanned operation of the cement plant.

The following is an example of the intelligent loading system developed and manufactured by Bremetz (Shandong) Machinery Co., Ltd. (referred to as "Bremetz") to introduce the functional characteristics of this type of product.

Loading efficiency: 2000-2400 packages/hour.

Single group depalletizing efficiency: 1000-1200 packages/hour; total efficiency: 2000-2400 packages/hour.

Vehicle passing height: 4 meters.

Loading specifications: total vehicle length 4-17.5 meters, vehicle width 1.6-2.8 meters.

Applicable models: high-rail vehicles, steel bar vehicles (the maximum steel bar recognition accuracy of existing vehicle scanning equipment is 5mm), special-shaped vehicles, flatbed vehicles, tricycles and other convertible vehicles.

The loading machine system is connected to the factory card through Ethernet to realize automatic acquisition of order information, and push information to the card after the order is completed, reducing the number of personnel in the loading process.

The loading machine system realizes interlocking control with packaging machines, palletizers and other process equipment through Ethernet to improve the automation of the loading process.

After the vehicle arrives, the loader's 3D laser radar automatically scans the vehicle, automatically obtains the vehicle position and compartment size, automatically calculates the stacking type, and automatically loads the vehicle.

The loader system has an identification system to detect the size information, spatial orientation, and tie bar position information of the current truck compartment, and feeds back to the control system, so as to adaptively adjust the loading system; the visual scanning system is used to automatically identify the length, width, height and other data of the vehicle, and automatically generate all data (including stacking data) to avoid the tie bar position.

The fully automatic loader is equipped with an interlocking function to interlock the entire transmission line.

The loader is interlocked with the packaging line manipulator. When the loader stops or fails, the packaging line manipulator automatically switches to pallet stacking mode. During the loading process, the vehicle is required not to move, and the loader automatically moves to load.

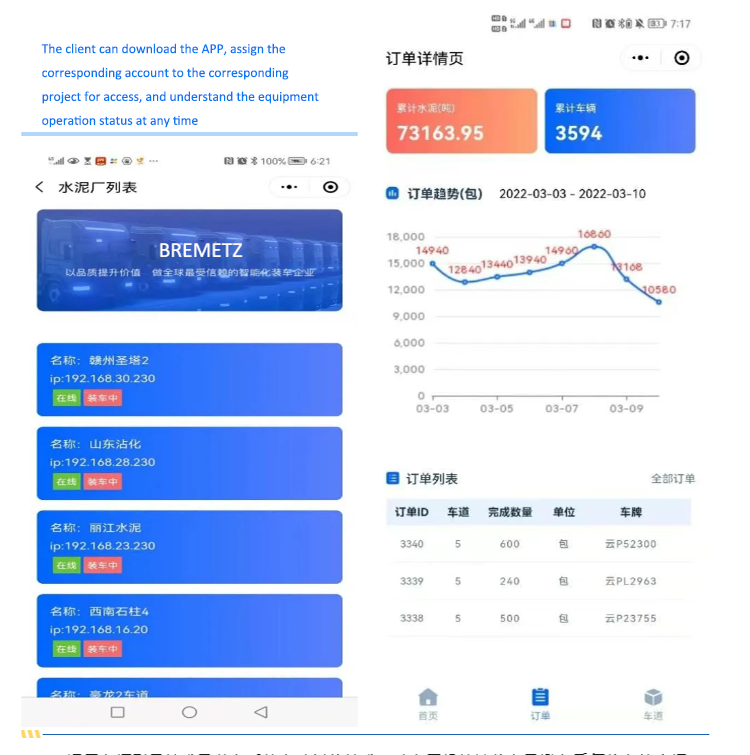

Data Center: Share big data with the original logistics queuing system, SAP system, and logistics information system of the cement plant, and open data interfaces.

Control system: High degree of intelligence, automatically calculate the cement stacking method according to the actual situation of the vehicle.

Remote control and data sharing: 24-hour remote monitoring and data system docking and real-time sharing.

The fully automatic loader is equipped with a counter, which can preset the loading volume. When the set value is reached, it has a linkage parking function.

After the loading is completed, the driver will be reminded to leave by sound and light. It has the function of segmented loading, low bag placement height, no bag slippage, and neat stacking.

It can realize mixed loading of multiple varieties of cement products. The equipment will reserve space for multiple loadings or manual loading space.

Two manipulators are used to take the bag, and the transmission system of each manipulator is equipped with two chain transmissions (as shown in Figure 3). The chain is selected according to double redundancy, that is, a single chain can meet the active load of the manipulator to ensure normal loading and shipment; in extreme cases, such as a chain breakage, the loader can continue loading after removing the damaged chain, and then choose the maintenance time according to the actual shipment situation.

The bag placement height is low, the maximum lifting stroke of the manipulator is 1.2 meters, and the bag taking station can extend the car to the maximum to place the material. The bag placement height is not higher than 40 cm, the stacking is neat, and the broken bag rate is less than 1‰.

Intelligent loading system technical architecture

Vehicle detection system

There are many types of trucks that load cement, including tricycles, flatbed trucks, C-type trucks, concave trucks, semi-trailers, high-sided trucks, flatbed trucks, etc. Faced with so many vehicle models, manual measurement is obviously a huge workload. The detection system uses a laser line scanning radar, which can scan the vehicle in all directions without blind spots, convert the scanned data into 3D point cloud data, and calculate the corresponding algorithm to obtain the vehicle model and the length, width, height and other data of the car body. The measurement accuracy can reach within 5mm, and the vehicle models cover all current models of bagged cement transport vehicles. This means that the intelligent loading system has very strong replicability in vehicle detection. The performance characteristics of the 3D pan-tilt measurement system are shown in the figure 4.

2. Fault prediction system

The core of the industrial Internet of Things is to collect equipment data. The fault prediction system is equipped with more than ten types of sensors. By installing an industrial Internet of Things gateway, the data on the equipment and sensors is collected in real time. The collected data is uploaded to the cloud time series database in real time. Combined with the data of the equipment management and material management modules, each component of the equipment is analyzed in real time; the cloud computing resources are used to perform big data calculations on historical data to obtain the current life trend chart of each component, and timely alarm notifications are issued for components that have failed or are about to fail, ensuring that the equipment is maintained and repaired in a timely manner without affecting the loading task. The operation and maintenance management platform of the intelligent loading system is shown in Figure 5

3. Other core functions

(1) The intelligent loading system is highly applicable to various bag types of cement, as shown in Figure 6

2) As long as the one-card system opens the interface, it can be seamlessly connected with the cement plant packaging workshop shipping system. At the same time, the loading system can also be connected with packaging machines, bag inserting machines, turning chutes and other equipment to achieve linkage control of the entire system.

(3) Nowadays, many cement plants' packaging machines have been in use for many years, so the bag types output by the packaging machines are relatively complex, including various abnormal bag types such as continuous bags, horizontal bags, T-shaped bags, etc. In order to solve these problems and ensure the stability of the loading system operation, the intelligent loading system is also equipped with a bag abnormality processing unit, as shown in Figure 7

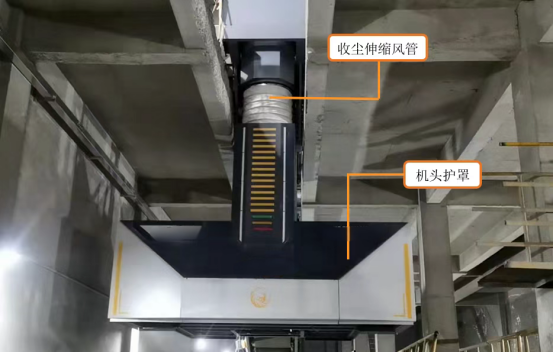

(4) Dust collection method: Design a fully enclosed space as the dust collection space within the palletizing robot and its motion range (i.e., the space directly above the bag dropping range), and collect the dust into the dust collection system through the dust collection pipe.

(5) The electrical control cabinet has a waterproof and dustproof structure with a protection level of IP54. It is equipped with a special cabinet air conditioner. The heat dissipation in the cabinet adopts internal air circulation to isolate the dust environment outside the cabinet. The wiring and threading adopt "wall-penetrating plate" and aviation plug. The control cabinet meets the IP54 protection standard. The electrical control cabinet is equipped with a grounding terminal. The production and installation of the control cabinet adopts the wiring trough in front of the board. The components in the cabinet are easy to maintain. There is a data placement box in the control cabinet to make the data easy to access and not easy to collect dust. A dust cover is installed on the wiring outlet leading out of the control cabinet. As shown in Figure 10

(6) Developing mobile APP and applying digital twin technology will allow factories to see the operating status of equipment, loading progress and loading volume at any time.

(7) The vehicle guidance technology and the automatic deviation correction technology of the loading system are used to help the driver park quickly and avoid the trouble of repeated parking. When the vehicle is parked within 15 cm to the left or right, the equipment can still achieve normal loading. As shown in the figure.

In addition, in order to adapt to different car models, Bremetz's automatic loading equipment has been continuously iterating and has now been upgraded to the BSBL-400 model, which can cover all open car models and bag types. the loading system is also suitable for loading bagged products such as flour, urea, potassium fertilizer, phosphate fertilizer, fertilizer, feed, chemical powder, etc

What industries are truck bag loader suitable for?

Truck bag loaders, also known as truck-mounted conveyor loaders or bag handling systems, are designed to automate and streamline the loading and unloading of bagged goods onto trucks. They are widely used in industries that handle bulk quantities of bagged products, improving efficiency and reducing manual labor. Here are the key industries where truck bag loaders are commonly employed:

1. Agriculture & Grain Processing

Loading bags of fertilizers, seeds, animal feed, and grains (e.g., rice, wheat, corn).

Used in silos, granaries, and agricultural distribution centers.

2. Food & Beverage

Handling flour, sugar, salt, coffee beans, powdered milk, and other packaged food products.

Common in food processing plants, warehouses, and distribution centers.

3. Construction & Cement Industry

Loading bags of cement, sand, plaster, and other construction materials.

Helps in bulk transportation to construction sites or retail distributors.

4. Chemical & Fertilizer Industry

Transporting chemical powders, fertilizers, and industrial raw materials packed in bags.

Ensures safe and dust-free loading of potentially hazardous materials.

5. Logistics & Warehousing

Used in distribution centers, freight terminals, and logistics hubs for loading/unloading bagged goods.

Improves loading speed and reduces labor costs in supply chain operations.

6. Retail & Wholesale Trade

Facilitates quick loading of bagged consumer goods (e.g., pet food, charcoal, detergent) onto delivery trucks.

Key Benefits of Truck Bag Loaders

Faster loading/unloading compared to manual labor.

Reduces physical strain and injury risks for workers.

Minimizes product damage (e.g., torn bags, spillage).

Adaptable to different truck sizes and bag types (e.g., 25kg, 50kg bags).