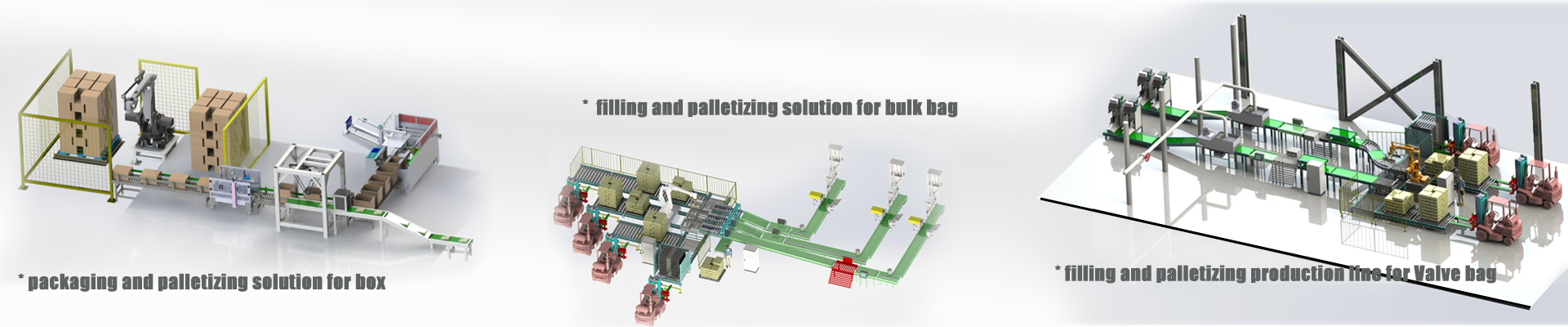

Composite material packaging palletizing conveyor line

The packaging and palletizing production line developed by bremetz for composite materials is a highly automated and intelligent production system specially used for the packaging, stacking and storage management of composite materials (such as carbon fiber, glass fiber, resin-based composite materials, etc.). The system integrates mechanical, electrical, sensing, control and information technology to achieve efficient, accurate and low-loss logistics operations, and is suitable for chemical, building materials, automotive, aerospace and other fields. The following are the key components and features of the production line:

1. Core components

(1) Automatic packaging unit

Function: Complete the weighing, bagging/wrapping, sealing, labeling and other processes of composite materials.

Equipment:

Automatic weighing machine: Ensure that the weight of each package of materials is consistent.

Heat shrink packaging machine or stretch wrapping machine: Protect the material from moisture and dust.

Label printer: Identify product information (such as batch, specification, QR code).

(2) Palletizing robot/robotic arm

Function: Stack the packaged composite materials on the pallet according to the preset pattern.

Type:

Articulated robots : highly flexible and suitable for complex pallet types.

Truss-type manipulators: high speed and stability, suitable for heavy materials.

End tools: adaptive fixtures (such as suction cups, mechanical grippers) to adapt to different packaging forms.

(3) Pallet handling system

Empty pallet supply: automatically transport empty pallets to the palletizing station.

Full pallet output: deliver the pallets that have been stacked to the storage or loading and unloading area.

Pallet library: store and manage pallets of different specifications.

(4) Conveyor system

Roller/belt conveyor: connects packaging, palletizing, and warehousing.

Diversion/merging device: optimizes logistics paths and improves efficiency.

(5) Intelligent control system

PLC+industrial PC: control equipment to operate in coordination.

Vision system: detects packaging integrity and pallet type accuracy.

Data management: connects to MES/ERP system to achieve production traceability.

2. Technical features

High adaptability: can handle composite materials of different sizes and shapes (such as plates, coils, and special-shaped parts).

Anti-damage design: avoid scratches on the surface of composite materials (such as soft contact fixtures, low-speed buffer control).

Energy saving and environmental protection: reduce packaging material waste and support recyclable pallets.

Intelligent optimization: automatically plan the optimal stacking type through algorithms to improve space utilization.

3. Application scenarios

Automotive industry: finished product packaging of carbon fiber components (such as battery boxes and structural parts).

Wind power field: segmented packaging and stacking of large composite blades.

Building materials industry: automated stacking of glass fiber reinforced panels.

4. Applicable Products:

Nanocomposites

Graphene or carbon nanotubes

Polymer blends

Talc or calcium carbonate Polymer composites

Metal matrix composites (MMC)

High strength fiber reinforcements

Silicon carbide or carbon fiber particles

Polymer matrix composites (PMC)

Glass fiber and carbon fiber fabrics

Polyester and epoxy resin

Glass fiber reinforced polymer (GFRP)

Polyester and epoxy resin bonded glass fiber materials

Hybrid composites

Carbon fiber and glass fiber

Ceramic matrix composites (CMC)

Silicon carbide, aluminum, boron carbide, carbon, ceramic matrix, silicon carbide, carbon or aluminum oxide

Natural fiber composites (NFC)

Natural fibers, wood, jute, cotton and flax,

Resin bonded natural fibers

Wood fibers added to polymers

Polyester resin matrix natural fiber reinforcements

Carbon fiber reinforced polymers (CFRP)

Aramid fiber reinforced polymers (AFRP)

Aramid reinforcements

Aramid fibers

Polyester and epoxy resin

Aramid/paper honeycombs

Epoxy resins

Functionally graded composites (FGC)

Metal matrix composites (MMC)

Ceramic matrix composites (CMC)

Polymer matrix composites (PMC)

Carbon fiber reinforced composites (CFRP)

Glass fiber reinforced composites (GFRP)

Aramid fiber reinforced composites

Metal fiber reinforced composites