Corrugated cardboard stacking robot loading line

The packaging industry is rapidly evolving with advanced automation solutions for corrugated cardboard processing, stacking, and palletizing. From corrugated machines to robot palletizers, businesses are adopting high-speed, efficient systems to optimize production and logistics. Below, we explore key machinery transforming the sector.

1. Corrugated Cardboard Stacking Systems

Efficient corrugated cardboard stacking ensures smooth material flow in printing, die-cutting, and packaging lines. Automated stackers organize sheets or boxes for further processing, reducing manual labor and improving productivity.

2. Paper Corrugated Pallet Machines

Sustainable packaging solutions are gaining traction, and paper corrugated pallet machines produce lightweight, eco-friendly pallets as an alternative to wood. These pallets are ideal for export, retail, and logistics due to their recyclability and cost-effectiveness.

3. Corrugated Machines (Corrugators)

The backbone of box production, corrugated machines manufacture cardboard by bonding fluted medium between liners. Key components include:

Single-facer (creates the fluted layer)

Double-backer (attaches the second liner)

Slitter-scorers (cut and crease sheets)

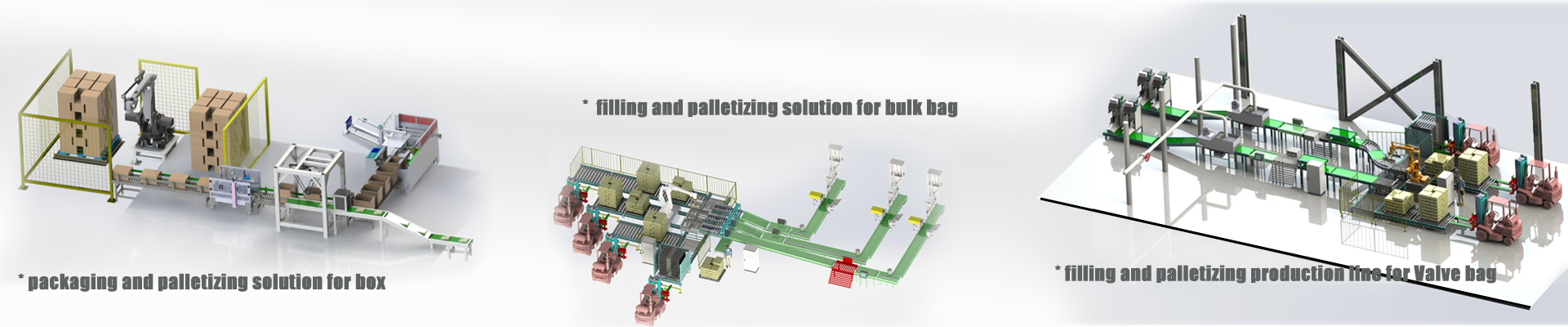

4. Robot Paletizador (Palletizing Robots)

Robotic palletizers automate the stacking of cartons, bags, or boxes onto pallets. They offer:

High-speed precision

Flexible pattern configurations

Reduced labor dependency

5. Palletizers for Cartons

Dedicated palletizers for cartons arrange boxes in optimized layers for shipping. Common types include:

Robotic palletizers (for mixed loads)

Layer palletizers (for uniform stacking)

Gantry palletizers (for heavy-duty applications)

6. Carton Forming Machines

Automated carton forming machines erect, fold, and seal flat cardboard blanks into ready-to-use boxes. These are essential for:

E-commerce fulfillment

Food & beverage packaging

Pharmaceutical industries

7. Automatic Packing Machines

End-to-end automatic packing machines handle sealing, labeling, and case packing. They integrate with:

Carton sealers

Stretch wrappers

Case erectors

8. Carton Sealing Machines

Carton sealing machines (tape or glue-based) securely close boxes for shipping. Options include:

Semi-automatic sealers (for low-volume operations)

Fully automatic sealers (high-speed production lines)

9. Palletizer Machines

A palletizer machine systematically stacks products onto pallets. Industries use them for:

Beverage & food (cans, bottles)

Consumer goods (cartons, bags)

Industrial products (heavy loads)

10. Carton Box Palletizers

Specialized carton box palletizers handle varying box sizes and weights, ensuring stable pallet loads for transport.

11. Palletizers for Carton Cases

Similar to box palletizers, these systems are optimized for different case dimensions, improving warehouse efficiency.

12. Robot Palletizers (Automated Palletizing Solutions)

Robot palletizers are revolutionizing logistics with:

AI-driven stacking patterns

Quick changeovers

Integration with WMS/ERP systems