Automatic palletizing machine

1. It can work 24 hours a day, and as long as there is material supply, palletizing can be carried out continuously.

2. Through precise programming and control, the automatic palletizer can stack products neatly and tightly on the pallet according to preset rules and patterns.

3. The number of layers and arrangement of palletizing can be reasonably adjusted according to factors such as product weight and size.

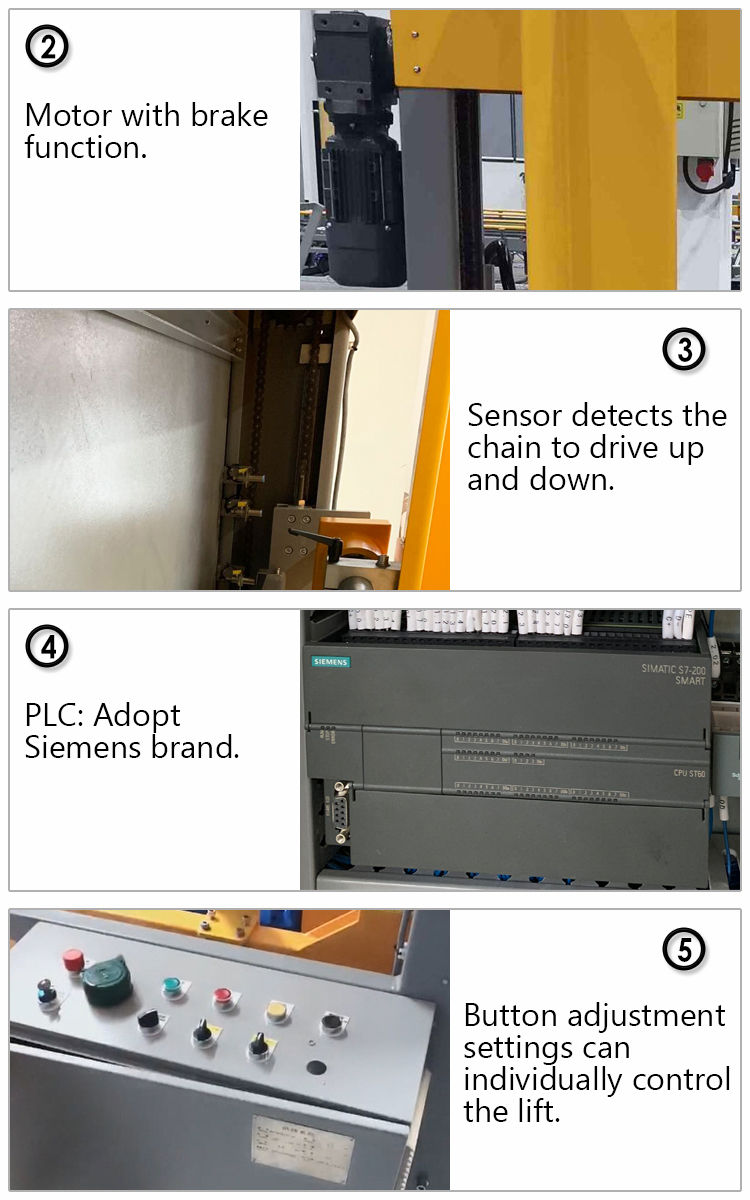

4. It is equipped with a variety of safety protection devices, such as light curtain sensors, safety fences, emergency stop buttons, etc.

5. By replacing different grippers or clamps, the automatic palletizer can adapt to the palletizing needs of products of different shapes, sizes and weights.

Automatic palletizer is an industrial automation equipment used to automatically stack goods or products onto pallets in a production line or warehouse environment. It is mainly used to stack various finished products, goods or packaged items on standard or customized pallets for easy transportation, storage and logistics management.

It can automatically grab products on the production line and stack them on pallets according to preset programs, without the need for manual operation one by one, and can achieve 24-hour continuous operation.

A variety of stacking modes can be set according to different needs, such as row-by-row, staggered, etc. The number of stacking layers, columns and rows can also be adjusted to form different stacking types.

With the help of visual recognition systems or sensors, the shape, size, position and orientation of products can be automatically identified to ensure accurate grasping and stacking.

With the help of visual recognition systems or sensors, the shape, size, position and orientation of products can be automatically identified to ensure accurate grasping and stacking.

Equipped with pallet storage and supply device, when a pallet is stacked, it can automatically push out the full pallet and replace it with a new pallet to continue stacking.

It is equipped with safety fences, light curtain sensors, emergency stop buttons, safety door locks and other devices to ensure the safety of operators and equipment.