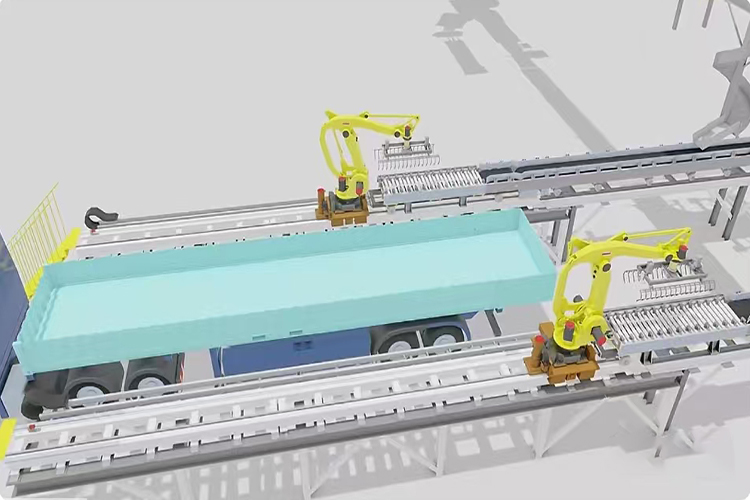

truck bag loading unloading system

truck bag bag loading unloading system is one of online robot arm truck loading system, Applicable industries:

1. Cement/building materials: 50kg cement bags, large-load 6-axis robot + vacuum suction cup, 600-2000 bags/hour

2. Fertilizer/feed: 25kg~40kg bags, medium-load robot + gripper

3. Food/beverage/boxed, bottled: BLMC robot + gripper

4. Chemical/plastic/ton bags, barrels: heavy-duty gantry robot + sling

5. Industrial salt bag loading and unloading truck syetem

The robotic arm loading system is an automated logistics equipment that uses industrial robots, intelligent vision and conveying systems to achieve efficient and accurate cargo loading operations. It is widely used in industries such as cement, fertilizer, feed, food, and chemicals, and is particularly suitable for loading bagged, boxed or regularly shaped items.

I. System composition

(1) Robotic arm (industrial robot)

Type: Mostly uses a 4-axis joint robot (such as BS-180-3100) robot (high-speed light-load scenario).

Load: Select according to the weight of the goods (for example, cement bags are usually 50kg/bag, and a robot with a load of ≥120kg is required).

End effector:

Vacuum suction cup: suitable for flat bagged materials (such as cement, flour).

Gripper/clamp: used for boxed or irregular items.

Magnetic suction device: metal packaging scenario.

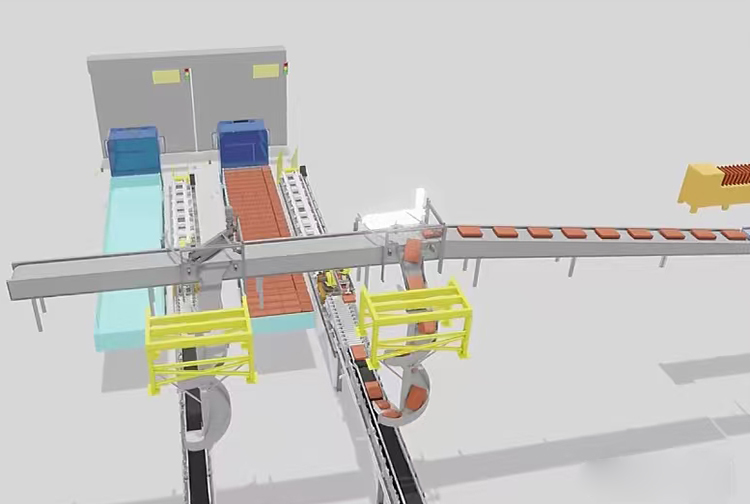

2) Conveying system

Feeding conveyor: belt conveyor, roller line or chain conveyor, which transports the goods to the working area of the robotic arm.

Diverter (optional): sorts multiple varieties of goods.

Weighing/inspection module: ensures that the weight or appearance of each piece of cargo is qualified.

(3) Visual positioning system

3D camera/laser scanner: identifies the size of the carriage, the stacking status of cargo, and the position of the vehicle.

Algorithm: generates the optimal stacking path through point cloud analysis and supports dynamic adjustment (such as vehicle movement or cargo offset).

(4) Control system

PLC (Siemens, Mitsubishi): coordinates the robot arm, conveyor belt, and sensor.

Human-machine interface (HMI): provides an operation panel and supports manual/automatic mode switching.

Data docking: can be connected to WMS (warehouse management system) or TMS (transportation management system).

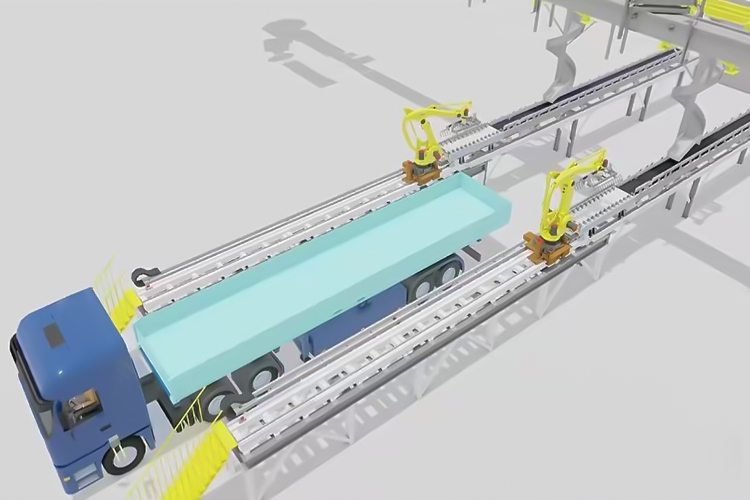

II. Workflow

1. Cargo loading: The conveyor transports the cargo to the robot arm grabbing station.

2. Vehicle positioning: The visual system scans the size of the carriage and the current loading status.

3. Path planning: The system calculates the optimal grabbing and stacking sequence (such as staggered stacking to prevent collapse).

4. Grabbing and placing: The robot arm completes loading according to the planned path and adjusts its posture in real time.

5. Completion feedback: After loading, the system sends a signal and the vehicle drives away.

III. Applicable industries

1. Cement/building materials: 50kg cement bags, large-load 6-axis robot + vacuum suction cup, 600-2000 bags/hour

2. Fertilizer/feed: 25kg~40kg bags, medium-load robot + gripper

3. Food/beverage/boxed, bottled: BLMC robot + gripper |

4. Chemical/plastic/ton bags, barrels: heavy-duty gantry robot + sling

5. Industrial salt bag loading and unloading truck syetem

IV. Selection recommendations

High dust environment (such as cement plants): choose dust-proof robot + dust removal system.

Heavy goods (such as ton bags): consider gantry robot

High precision requirements (such as medicine boxes): with high-resolution 3D vision system.