Truck bag loader for pvc rubber powder

Typical application scenarios of Truck bag loader

1. Building materials industry

Bagged cement/mortar/lime/gypsum/putty/rubber/Propane/starch powder: Through the robot arm to grab and stack, solve the problems of low efficiency of manual loading and dust hazards. The bagged cement robot adopts multi-axis linkage control to achieve high-speed and accurate loading.

2. Chemical and food industry

Bag loading: bremetz's robot can grab 1-4 bags at a time, support pallet-free operation, and reduce logistics costs.

3. Sodium carbonate bag loading robot: supports 20kg/50kg bag material loading, uses laser scanning and AI planning, is compatible with multiple models, and improves efficiency by 300%.

4. Specially used for stacking and loading light bagged materials such as flour bags.

5. Specially used for feeding bag loading

6. Specially used for urea bag loading, grabs 3 bags at a time, and loads efficiently.

7. Suitable for various truck models.

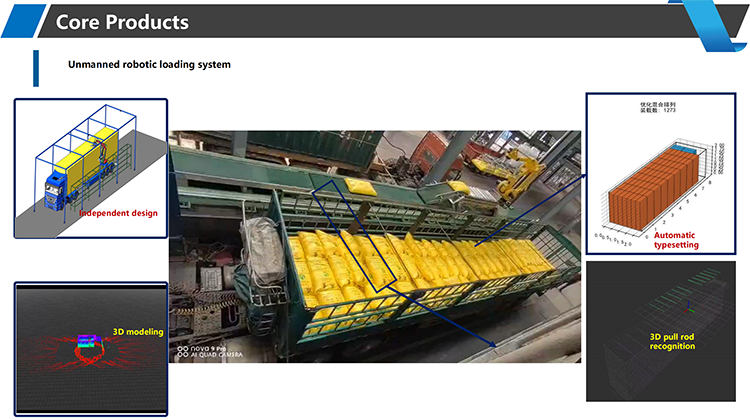

The following is an introduction to the truck bagging machine produced by bremetz

I. Core structure and working principle

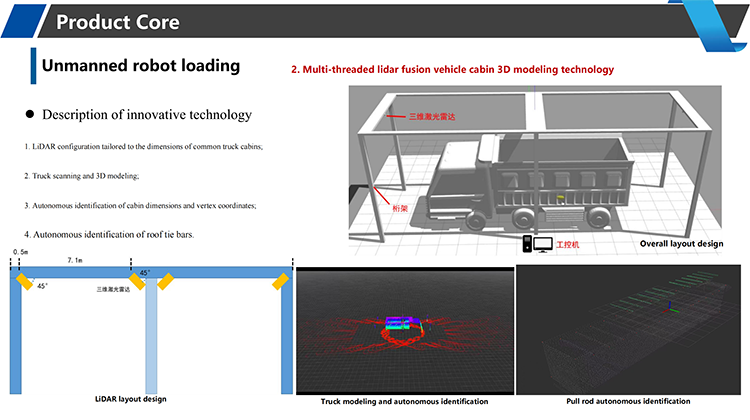

1. Multi-stage telescopic arm design

Truck bag loading and unloading machines usually adopt a multi-stage telescopic arm structure (such as a four-section telescopic arm), which can achieve a wide range of telescopic movement through hydraulic drive and wire rope linkage. The robotic arm consists of the first to fourth telescopic arms, which are driven by hydraulic cylinders. The telescopic stroke can reach 3 times that of the hydraulic cylinder, covering a large area of the truck compartment.

Drive mode: The hydraulic system is combined with PLC control to ensure the accuracy and stability of the movement.

Sensor configuration: Magnetic scale sensor, rising/falling position sensor monitors the telescopic position in real time to prevent over-limit collision.

2. End effector adaptability

Clamp type: including vacuum suction cups, clamping claws, etc., which can adapt to different materials such as bagged flour, ton bags (such as mortar, chemical raw materials).

Flexible gripping technology: Some robotic arms are equipped with pressure sensors and visual systems, which can automatically adjust the clamping force to deal with packaging deformation or damage.

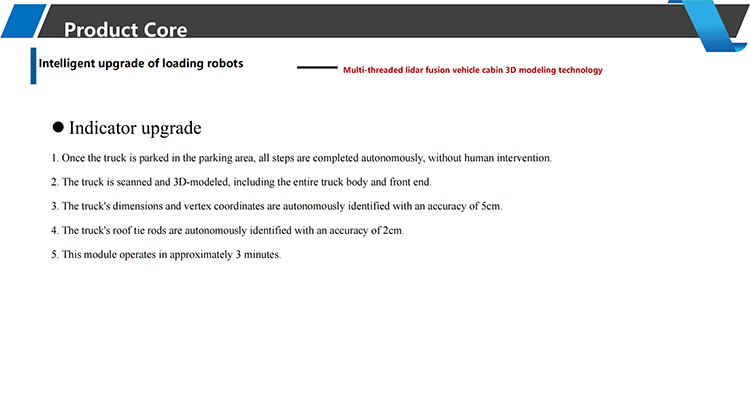

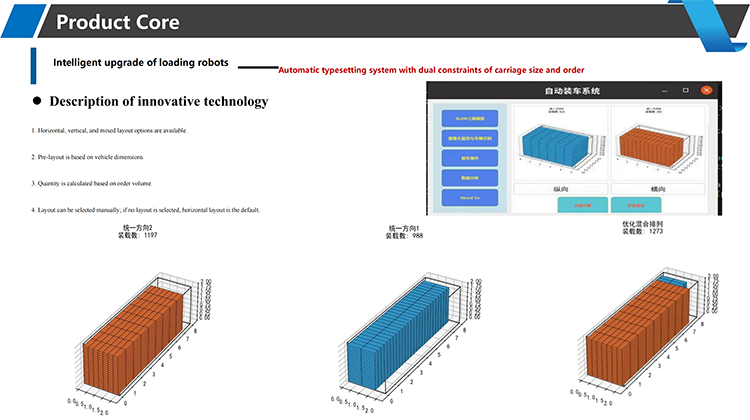

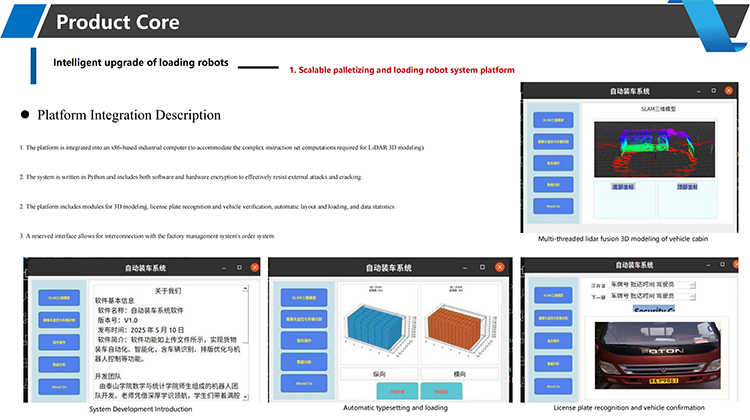

PLC and AI integration: PLC controls the robot arm motion process and combines AI algorithm to optimize path planning. The loading manipulator produced by bremetz uses laser scanning and 3D reconstruction technology to adjust the stacking path in real time to meet the needs of different vehicle models.

Multimodal positioning: Integrating laser SLAM, visual odometer and other technologies, the positioning accuracy reaches ±5mm, which can adapt to complex environments.

II. Technical advantages and innovations

1. Efficient automation

Replacing manual handling, a single machine can handle 600-800 bagging cycles per hour, and the efficiency is increased by more than 3 times.

Support continuous operation, for example, the container bag robot can achieve 7×24 hours operation with a failure rate of less than 0.5%.

2. Multi-scenario adaptability

Vehicle type adaptation: The intelligent scanning system is compatible with high-rail vehicles, flatbed vehicles and other models, and the stacking strategy is automatically adjusted.

Material diversity: It can handle a variety of specifications such as bagged cement, lime, gypsum (25-50kg), ton bags (0.5-2.5 tons), and the load range is from 50kg to 1.5 tons.

3. Safety and stability

The anti-sway control system and collision sensor avoid shaking during operation and ensure that the materials are stacked stably.

The explosion-proof design (such as ATEX certification) is suitable for hazardous environments such as chemical industry.

III. Typical application scenarios

1. Building materials industry

Bagged cement/mortar/lime/gypsum/putty powder: Through the robot arm to grab and stack, solve the problems of low efficiency of manual loading and dust hazards. The bagged cement robot adopts multi-axis linkage control to achieve high-speed and accurate loading.

2. Chemical and food industry

Bag loading: bremetz's robot can grab 1-4 bags at a time, support pallet-free operation, and reduce logistics costs.

3. Sodium carbonate bag loading robot: supports 20kg/50kg bag material loading, uses laser scanning and AI planning, is compatible with multiple models, and improves efficiency by 300%.

4. Specially used for stacking and loading light bagged materials such as flour bags.

5. Specially used for feeding bag loading

6. Specially used for urea bag loading, grabs 3 bags at a time, and loads efficiently.