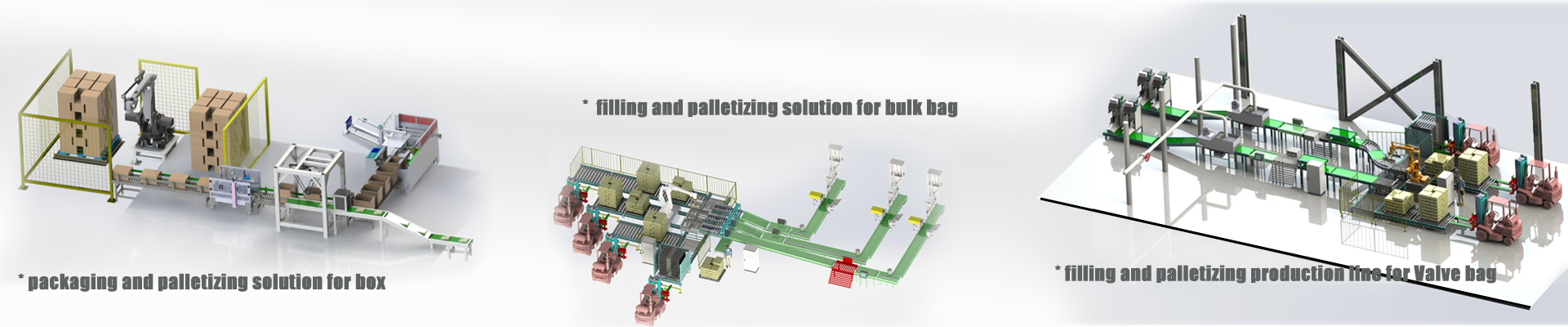

Mortar dry mix gypsum putty powder cement concrete automatic bagging automatic filling automatic stacking production line

The automatic bagging automatic filling automatic stacking production line produced by bremetz specializes in automatic bagging, automatic filling and automatic palletizing of bags in the mortar cement dry mix gypsum concrete putty powder industry.

I. Core components of the production line

1. Filling part

Including automatic filling machine, bag feeding machine, heat sealing machine, etc., supporting a variety of packaging materials (such as woven bags, paper bags), the packaging specifications are usually 20-50kg/bag, and the packaging speed can reach 800-1600 bags/hour.

2. Conveying and detection part

Equipped with bag-reversing conveyor, re-inspection scale, rejection device, etc. to ensure the accuracy of packaging weight (≤0.2%), and complete standardization through shaping machine and inkjet printer.

3. Palletizing part

Use gantry frame palletizer, combined with PLC control and touch screen operation to realize pallet stacking, support teaching programming to flexibly adjust the palletizing mode.

4. Automatic pallet supply system

II. Typical application scenarios

1. Dry mortar production

Suitable for automated packaging and palletizing of bagged products such as gypsum mortar and thermal insulation mortar, and the sealing design reduces dust leakage.

2. Cement and building materials industry

Replace manual feeding and handling to improve the workshop environment. For example, a building materials factory in Weishi uses a fully automatic line to achieve integrated feeding-mixing-packaging.

3. Chemical and feed processing industry

Processing fine powder and granular materials such as fertilizers and feeds to support packaging needs of multiple industries (such as petrochemicals and grain processing).

The production line integrates intelligent configuration control and network management, which is suitable for multiple industries such as petrochemicals and metallurgy, with a packaging capacity of 1,600 bags/hour.

Through the above solutions, enterprises can significantly improve packaging and palletizing efficiency (such as reducing manual speed from 2 minutes/pallet to 20 seconds), while reducing comprehensive operating costs by about 30%. The specific selection needs to be combined with production capacity requirements, material characteristics and budget