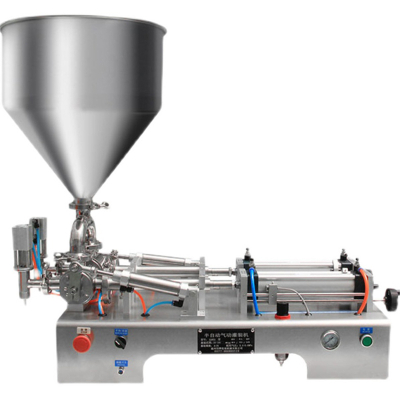

Automatic valve packing machine

1. Efficient production: It can automatically complete a series of packaging processes such as material conveying, metering, filling, and sealing without a lot of manual intervention.

2. Save manpower: It reduces dependence on manual operation, reduces labor costs and labor intensity.

3. High-precision weighing system: Equipped with advanced weighing sensors and precise metering control devices, it can accurately measure and control the filling amount of materials.

4. Stable performance: It adopts weighing elements and control systems with high comprehensive accuracy and good long-term stability, which can maintain stable metering accuracy during long-term continuous work.

5. Easy to use: It has a simple and intuitive operating interface and a user-friendly control system. Operators only need simple training to master the operation of the equipment.

6. Convenient maintenance: The structural design of the equipment is reasonable, and it is easy to carry out daily cleaning, maintenance and repair work.

The automatic valve packaging machine adopts an integrated design, compact and reasonable structure, and scientific layout of each component, aiming to achieve efficient and stable valve packaging operations. The overall frame is constructed of solid metal material, with good stability and durability, and can withstand long-term high-intensity workload.

Equipped with high-performance conveyor belt and precise material pushing device. The conveyor belt is made of special material with good wear resistance and corrosion resistance, and can smoothly convey various types of valves.

The use of high-precision weighing sensors and advanced metering control algorithms can accurately measure valves of different specifications and materials. The weighing sensor has high sensitivity and stability.

In order to improve packaging quality and production efficiency, the automatic valve packaging machine is also equipped with some auxiliary function systems. For example, the dust removal system effectively removes the dust generated during the packaging process through fans and filters, keeps the working environment clean, and also reduces the pollution of dust to equipment and valves, extending the service life of the equipment and the shelf life of the valve.