Fully automatic roller conveyor

1. The equipment can realize the automatic conveying of materials from the starting point to the designated location without a lot of manual intervention.

2. The rolling friction between the rollers is small, and the materials can move quickly and smoothly on it.

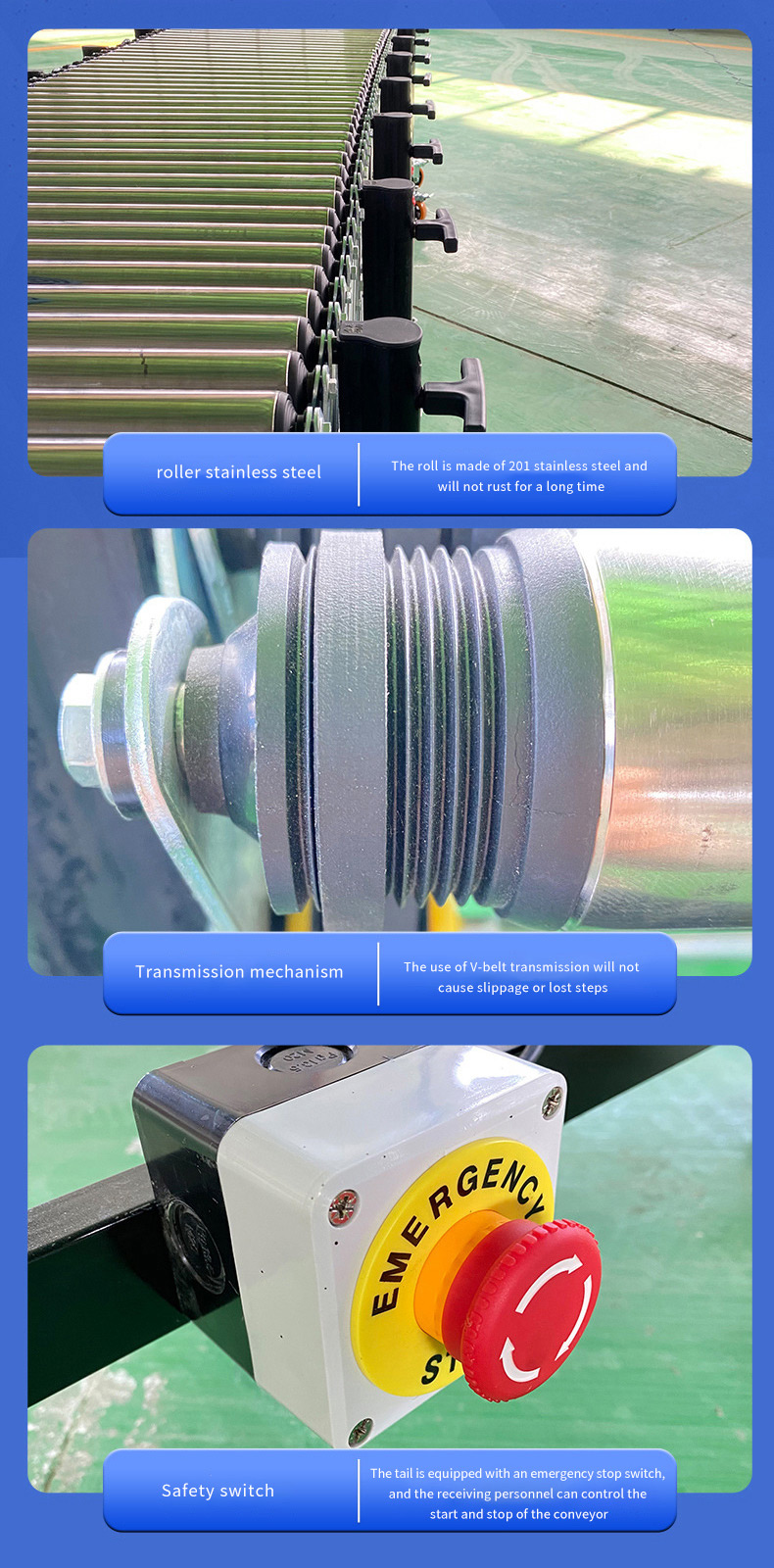

3. The structure is reasonably designed, using high-quality materials and advanced manufacturing processes, and the key components are strictly screened and tested.

4. The structure is relatively simple, and the rollers and other components are easy to disassemble and replace.

5. It is composed of multiple standard modules, which can be flexibly combined into various conveying routes according to different production sites and process requirements.

Fully automatic roller conveyor is a kind of equipment that uses the rotation of rollers to realize automatic material conveying. It combines advanced automation control technology and precise mechanical manufacturing technology to achieve efficient and accurate material conveying and is widely used in production and logistics links of various industries.

Realize automatic loading, conveying and unloading of materials, reduce manual intervention, reduce labor intensity and improve production efficiency.

The friction between the rollers is small, and the resistance of the material during transportation is small, which can achieve fast and efficient transportation. At the same time, multiple conveyors can be combined and used according to production needs to form a complex conveying system.

It can convey materials of various shapes, sizes and weights, such as cartons, wooden boxes, pallets, parts, etc. By adjusting the roller spacing and conveying speed, it can adapt to the conveying requirements of different materials.

With high-quality components and advanced manufacturing technology, the equipment operates stably with low failure rate. At the same time, it is equipped with complete safety protection devices, such as emergency stop button, overload protection, deviation protection, etc., to ensure the safety of operators and equipment.

The structure is simple, and the parts are easy to disassemble and replace. Daily maintenance work mainly includes checking the operating status of the equipment, cleaning the roller surface, lubricating the transmission parts, etc., and the maintenance cost is low.